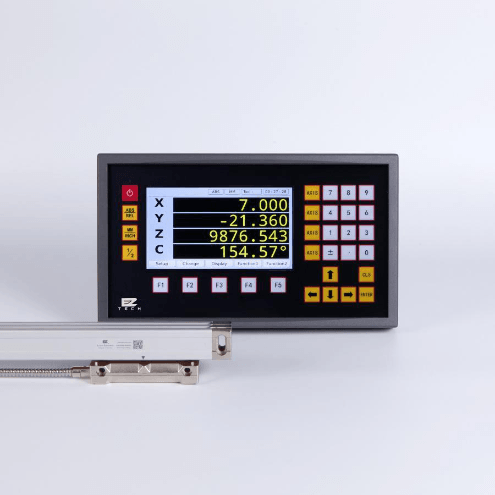

Z500 Series LCD Displays

Description

Z500 series of EZ TECH DRO Counters offer multiple different types of LCD display options for both 2- and 3-axis milling and lathe machines, including Bluetooth capability.

Specifications

EZ TECH® DRO

- 7" TFT screen for displaying four axis of sensor signal input.

- Programming with the assistance of 2D graph and simulation demonstration.

- Easy and friendly operation interface, personalized background supporting arbitrary combination of 7 colors.

- Data transport by Bluetooth, synchronous display with smart terminals, for the application of multi-windows interactive operation in large equipments.

- 5MHz sampling frequency for each axis of sensor signal inputs.

- I/O ports for programmable inching control.

| Type | Function name | For milling machines and boring mills | For lathes | For grinders | For EDM |

|---|---|---|---|---|---|

| Feedback | connection to EIA-422A signals | • | • | • | • |

| linear axis | 6 | 3 | 2 | 3 | |

| rotating axis | 2 | 0 | 0 | 0 | |

| linear compensation | • | • | • | • | |

| multi-point compensation | 200 | 40 | 40 | 40 | |

| Display | 7" color TFT screen | • | • | • | • |

| number of axis | 4/6 | 3 | 2 | 3 | |

| radius/diameter display | ○ | • | ○ | ○ | |

| half vaule display | • | ○ | • | • | |

| mm/inch conversion | • | • | • | • | |

| fine/coarse resolution conversion | • | • | • | • | |

| absolute/relative display conversion | • | • | • | • | |

| display off | • | • | • | • | |

| Functions | number of zero points | 200 | 200 | 200 | 200 |

| number of tools | ○ | 50 | ○ | ○ | |

| axis preset | • | • | ○ | ○ | |

| calculator | • | • | • | • | |

| quick setup | • | • | • | • | |

| centering workplace | • | • | • | • | |

| bolt holes drilling along the circumference | • | ○ | ○ | • | |

| linear bolt holes drilling | • | ○ | ○ | • | |

| grid pattern drilling | • | ○ | ○ | • | |

| find zero point | • | • | • | • | |

| angle measuring | • | • | ○ | • | |

| slope calculation | • | ○ | ○ | ○ | |

| axial processing | ○ | • | ○ | ○ | |

| transverse processing | ○ | • | ○ | ○ | |

| on-screen guided help with graphics | • | • | ○ | • | |

| inclined plane machining | • | ○ | ○ | ○ | |

| smooth R cutting for arc-shaped surface | • | ○ | ○ | ○ | |

| digital filtering for de-wobbling | ○ | ○ | ○ | • | |

| gradual rectangular lumen processing | • | ○ | ○ | ○ | |

| taper measuring | ○ | • | ○ | ○ | |

| matching output | ○ | ○ | ○ | • | |

| storage or zero points | • | • | • | • | |

| storage of multi-workpiece programs | • | • | • | • | |

| data transport by 485 bus | • | • | • | • | |

| analog signal output port | ○ | 1 | ○ | ○ | |

| digital signal I/O port | • | • | • | • | |

| data transport by Bluetooth | • | • | • | • |